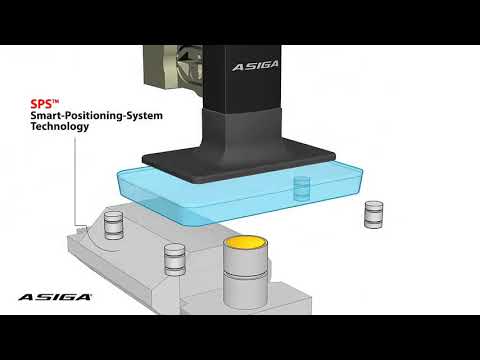

Did you know: 3D printed parts are produced layer by layer. An important factor in achieving production consistency and repeatable accuracy is ensuring that each layer is formed at the correct thickness. This has to be done layer by layer

Asiga’s SPS ™ -technology (Smart Positioning System) ddetects the actual position of the build platform during each production layer, allowing the printer to nestle between each layer approach before the layer is cured.

Regardless of material viscosity, layer cross-section or printer deflection, Asiga’s SPS ™ technology applies all of these variables to form layers with accurate thickness, giving you the consistency you expect and require from a 3D printer. The SPS technique measures and adjusts where necessary, fully automated and as a standard feature with every print job.

This SPS ™ technology from Asiga is a combination of various technologies that are standard on every Asiga 3D printers.

Are you getting consistent results with your 3D printer?

Asiga SPS system – how it works: